2024 marks 20 years since the XJ40 finally became the car it could have been from day one – the X300 XJ

Ford Motor Company’s European model launches for 1994 were a decidedly mixed bag: on the one hand, we had a thoroughly sensible joint venture with VW Group to build people carriers in Portugal which would ultimately prove very lucrative, while on the other hand we had the seemingly lunatic decision to allow the curiously styled Ford Scorpio into production. Sitting somewhere between the two and slipping somewhat under the radar was the restrained elegance of Jaguar’s fifth generation XJ saloon: what we know as the X300.

Launched in September 1994 and displayed at the Paris Motor Show the following month, the Jaguar was as neat as the Scorpio was comical and although it was touted as an all-new model it was effectively a top-and-tailed version of its predecessor, the XJ40.

Indeed, it’s the history of the XJ40 which informs the significance of the X300 generation, since it was that car’s drawn-out gestation which meant that it was ripe for replacement even as it was launched in 1986. By the time Jaguar had become part of the FoMoCo empire in 1989, the XJ40 was outclassed by the German rivals, with newcomer Lexus coming up quickly on the outside.

Work had in fact begun on an all-new replacement as early as the late ’80s under codename XJ90, but when Ford management baulked at the projected $500m cost of the project the idea was put on the back burner as the investment was diverted into the antiquated production facilities.

Instead, the XJ40 received a major makeover which it was claimed at the time was to accommodate the V12 engine, but with hindsight was clearly Ford’s longer-term strategy to update the platform to allow it to continue as long as possible.

Costing some £35m, the update involved the modification of 140 individual panels, while a reduction in the number of separate pressings made a big difference to the overall quality and refinement of the car. Particularly obvious was a new one-piece pressing of rear wing and C-pillar which removed the awkward join at the base of the pillar, while welded rather than bolted door frames meant better sealing. With an eye to the unnerving accuracy of Lexus, panel gaps were reduced by five per cent, while semi-flush side glazing improved wind noise and bonded front and rear glass further improved torsional rigidity.

The revised XJ40 would be launched in 1993 but would be a short-lived offering, since its replacement would be announced the following year.

Press reports at the time put the development cost of the X300 at £200m, yet it was essentially the nose and tail of the abandoned XJ90 project grafted on to the centre structure of the XJ40. This approach – complete with the awkward word ‘Retrolutionary’ coined by Jaguar to describe it – was more sensible than it sounds, however: market research in the USA had determined that the distinctive face of the Series XJs was what defined Jaguar in the minds of customers and the XJ90 had been styled with familiar Jaguar curves.

To describe the X300 as a new nose and tail on the XJ40 is also factually incorrect, since every outer panel was changed by Geoff Lawson’s design team while integrating the four-lamp front end, reshaped bonnet and rear wings. Modern detailing was adopted including colour-coded polyurethane bumpers which could resist minor bumps.

Similarly, the interior would be immediately familiar to XJ40 owners, yet in reality almost every detail had changed: the perceived quality of switchgear was improved and the shapes of the dashboard and door trim mouldings were softened. The X300 also received new seats produced by US supplier Lear in a new plant in Coventry, which were both lighter and more comfortable than the XJ40 items while providing improved rear legroom and greater adjustment – both areas where Jaguar’s cramped interior still put it on the back foot against the Germans.

Accommodation and practicality were further improved by using a space saver spare wheel which could be stored under the boot floor, widening the boot space to allow those crucial golf bags to fit.

The X300 was assembled at Jaguar’s traditional home, the Browns Lane plant in Coventry using bodyshells assembled and painted at Castle Bromwich. These production facilities received more than half of the £200m cost of the X300 programme, gaining Ford’s top ‘Q1’ status as a result. The old-fashioned production line, which had originally been bought at a knock-down price by William Lyons from Standard in the 1950s, was replaced by a more modern ‘doors off’ overhead conveyor system with powertrain assemblies fitted from below, while panels were electronically measured before being assembled into shells which were themselves measured at 1400 points.

Modern just-in-time production logistics were employed, with entire sub-assemblies contracted out to external suppliers. Seats and instrument panels were made by Lear Corporation close by in Coventry, but leather and veneer seats were provided by Jaguar’s in-house trim shop. The cars were painted using colour-matched primer rather than the standard grey used on the XJ40, while the coachlines were applied by hand rather than using tape. The end result was that Jaguar claimed a 1993 car suffered one-seventh of the ‘Things Gone Wrong’ [TGW] rating of a 1990 car.

Curiously, whereas fellow Ford subsidiary Aston Martin became something of a laughing stock for the many hand-me-down components inside the DB7, from Escort heater controls to MX-5 door handles, Jaguar escaped the same treatment and Ford switchgear is notable for its absence. Not that there isn’t any Ford componentry in the XJ of course, it’s just that it’s hidden behind the scenes, as is Ford’s expertise in production. This was perhaps more obvious when it came to the electrical system, for which Jaguar claimed class-leading reliability courtesy of gold-plated, ‘low mating effort’ connectors and no less than 90 fuses protecting the system.

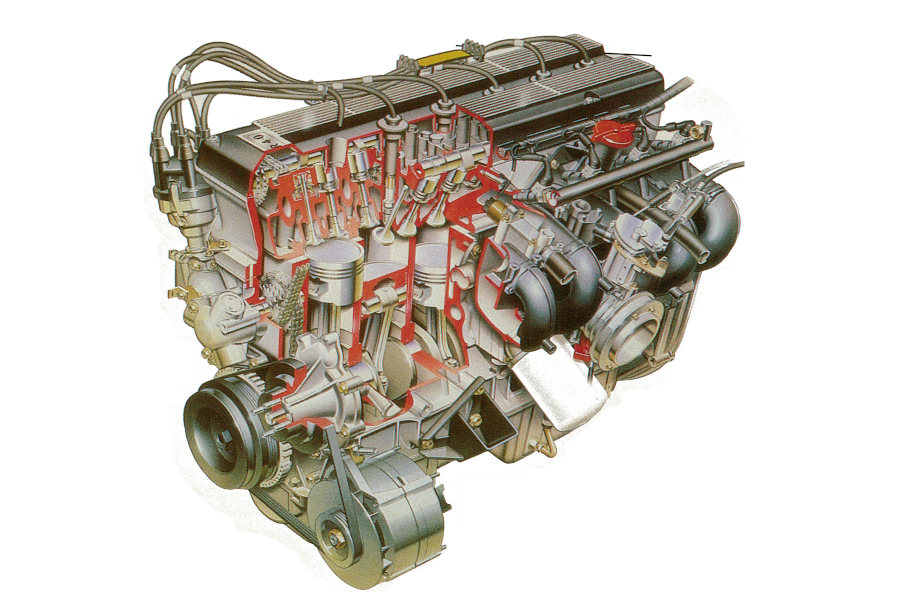

Like the car’s structure, the running gear was familiar from the XJ40 yet also significantly overhauled. The AJ6 engine gained coil-on-plug ignition, revised cylinder head, cams and pistons and a switch back from cast iron to forged steel crankshaft. A full electronic engine management system was also added, combining injection and ignition and allowing communication with the electronic control of the ZF gearbox in order to retard the timing momentarily during upshifts in the interests of refinement. The changes were sufficiently significant to warrant a change in designation to AJ16, with the new engine offered in 3.2-litre, 216bhp form or 4-litre, 246bhp trim.

Meanwhile, the long-serving V12 was upgraded to six litres and good for 318bhp, although its very existence was rendered precarious by an entirely new departure for Jaguar: the supercharged AJ16 developed to power the XJR.

Using a belt-driven Eaton M90 supercharger (so named on account of its displacement of 90 cubic inches per pulley rotation) running at 10psi of boost, the result was a headline output of 321bhp at 5000rpm and 378lb.ft torque at 3050rpm. Using a supercharger allowed a flatter power delivery than the laggy turbo installations of the day and gave the XJR torquey, muscular performance which made it a credible rival to the likes of BMW’s M5.

Amusingly, the idea of the XJR was initially unpopular with Jaguar management, with boss Nick Scheele eventually giving the project the green light expecting to sell only a couple of hundred cars. In the end, over 6500 were produced – or to put it another way, more than twice as many as the V12.

The underpinnings remained the familiar coil-sprung layout, albeit with bigger rear brake discs and calipers to counter criticisms that the rears could get unacceptably hot on the XJ40 in spirited driving. The spring, damper and anti-roll bar settings were all revised however reflecting the switch to a standard 16-inch wheel on all but the XJR.

The standard suspension was offered on XJ6, Sovereign and Daimler Six, with a slightly stiffer package for the XJ Sport model and a firmer one for the XJR. A further package was used for the V12-engined cars.

The model range for the UK initially comprised the entry-level XJ6 in 3.2 or 4.0 form, the luxury Sovereign trim offered in both 3.2 and 4.0 form and the XJ12. The car was also offered as the lavishly trimmed Daimler Six with the 4-litre AJ16 engine and in V12 form as the Double Six. In 1995 a long-wheelbase option was added for all models except Sport and XJR, later made standard for the Sovereign and Daimler models.

The X300’s short life meant few model changes, with the limited edition Daimler Century offered in 1996 to celebrate the marque’s 100 years, while a run-out model was offered the same year in the form of the XJ Executive which offered some £5000-worth of options on the entry-level 3.2.

The end of production came in April 1997 for the V12 cars and for the six-cylinder cars in September, when that XJ40 platform was repurposed once again. This time it was to receive the all-new AJ-V8 engine and a new codename, X308 in which form it was destined to soldier on with justifiable pride until the aluminium-bodied X350 generation was announced in 2002.