The Morgan Plus 8 offers brilliant performance in an elegant, retro-styled shell. Here’s what you need to know to secure a good example

The story of the Morgan Plus 8 arrival is an odd one. It was well known that during the 60s a four-cylinder sports car was no longer big enough to keep up with customer demand. Triumph’s answer to this problem was to produce a six-cylinder TR5, but the problem for Morgan was that the straight-six was simply too long to fit in the existing 4/4’s body. Lotus’s twin-cam was considered but regarded as too fragile, while Ford’s V6 was too tall and heavy.

With Morgan left in a bit of a predicament, it was Rover that came to the rescue. Peter Wilkes, then director of Rover, visited Morgan in an attempt to acquire Peter Morgan’s business. Although Morgan politely declined the offer, the two reached an agreement for supply of the recently developed Rover V8 engine. The lightweight design was still in the process of being adapted from the Buick/Oldsmobile unit used in Buick cars from 1960 to 1963.

Production of the Plus 8 began in 1968 and ran for 36 years until 2004. In this period, 6000 examples were built and many are still on the road. Over its lifespan, however, the car’s body and technical specification changed significantly, with the last of the breed coming with a fuel-injected engine and five-speed transmission.

Here’s your guide to buying the best-possible example of the Morgan Plus 8.

Bodywork

The Plus 8 body came in one style, a two-seat open tourer, although a single hardtop coupe was produced on chassis number R7317. The coupe proved too complicated and far from economically viable, leaving Morgan to stick to its winning formula of open-top driving.

The Morgan Plus 8 was wider and more imposing than its predecessors. In the early cars, the overall width was 4ft 9in, with a track of 4ft 1in. This spread wider in years to come when in August of 1973, the track was measured at 4ft 3in at the front and 4ft 4in at the rear, with the total width equalling 4ft 11 in. This changed again in 1977, when the wings were replaced with steel instead of aluminium, width stretching to 5ft 2in, with a 4ft 5in track at the front and 4ft 6in in the rear. A final increase in width came in 1981 at 5ft 3in, this time to accommodate new alloy wheels.

Until 1986, the steel chassis had little protection from the weather, so if the chassis has not been replaced then it is bound to be rusty. Of particular interest is rust in the side members, around the hole which supports the engine mounting brackets, and at the junctions where the crossmembers meet the main Z-section side members.

The simplest way to check for rust is to tap along the chassis with a screwdriver. A different tone, or a dull note, will indicate rust. Do not patch weld this: it is far better (and safer) to replace the whole chassis member, which can be ordered from the Morgan factory.

A good option here is to have the chassis shot-blasted and coated. It has also been noted that drilling a few holes into each of the crossmembers and filling with Waxoyl can further prevent rust.

The condition of the ash body frame all depends on how the car has been stored and whether the car it’s been subjected to extreme damp for a period of time. If not dried off properly, for example, a Plus 8 can rust within 10 years. Luckily, rot is easy to spot where you can see the wood: place your fingernail onto the wood and if you can press it then it’s more than likely rotting. Similarly, if an end looks a bit knobbly, this also indicates rot.

Door frames can also be an issue. If the door appears difficult to shut, this can indicate problems, and similarly if the hinge pillar tries to twist or move with the door, rot could be to blame. If there is any rot here, or anywhere for that matter, the whole section must be replaced. The sections are inexpensive, but as the body needs to be removed, labour can be costly.

Engine and transmission

As mentioned previously, Morgan made use of the then-new Rover V8 engine. The Morgan Plus 8 initially ran the engine in exactly the same state of tune as the Rover P6 3500, with a 3528cc capacity, although some V5s will say 3532cc, as this was written in error.

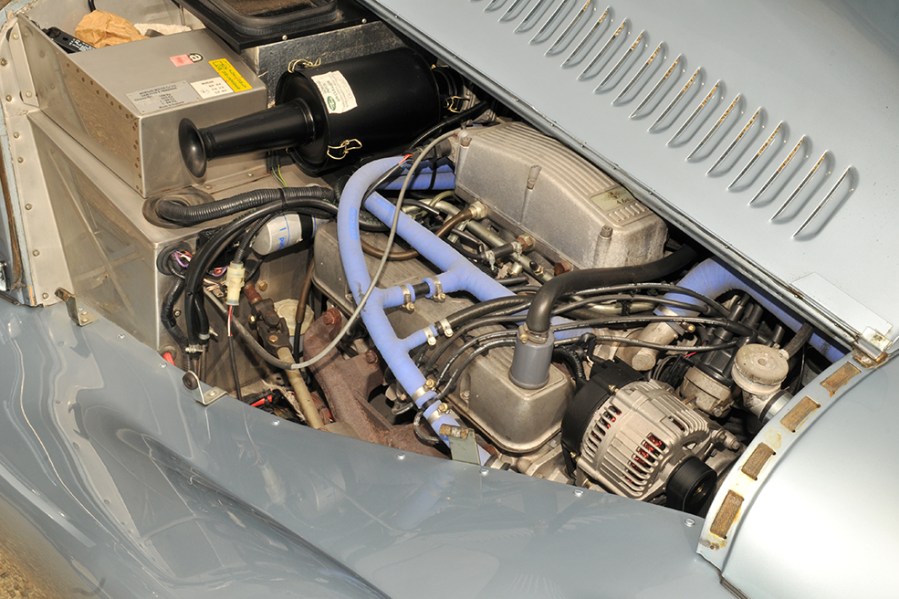

Getting the engine into the Morgan was a tight squeeze and required a few modifications. For starters, the airbox was ‘carefully’ modified by placing a plank of wood on it and hitting it with a hammer to create a gap for the bonnet hinge to sit in.

Rover claimed 151bhp and 210lb ft of torque offered at 2750rpm. However, with five-star fuel being phased out, in 1973 power output was reduced to 143bhp and 202lb ft of torque due to the compression ratio change from 10.5:1 to 9.35:1.

In 1976, the engine was replaced with that used in the Rover SD1, meaning power was upped to 155bhp. This was upgraded in 1983 to a fuel-injected unit from the SD1 Vitesse. The capacity remained the same but featured re-profiled inlet ports for improved flow and a higher compression ratio of 9.75:1, offering 190bhp and 220lb.ft of torque.

From June 1990, the engine used switched to a 3946cc Range Rover unit producing the same power outputs as before. The very latest Plus 8 models used a 4.8-litre BMW V8 producing a mammoth 367bhp and 370lb.ft of torque.

As Morgan has used a multitude of engines through all of its models, available parts are determined by other models they appeared in. Unfortunately for the Plus 8, the only other car that shared the Rover 3500S engine was the P6, meaning some parts are impossible to get hold of: for example, the cast exhaust manifold. As a result, buyers of the 4/4 rather, than the Plus 8, are in a better position for an easy restoration. On the flip side, however, the Rover engine is regarded as extremely strong, with six-figure mileages being perfectly doable given proper maintenance.

The main issue to note is with the retention of the cylinder heads. While the early Rover V8 engines had 18 retaining bolts for each head, the later SD1 engines had an outer row of four bolts missing, creating potential uneven stress. This could result in unburnt petrol and exhaust fumes contaminating the engine oil, resulting in bore wear and cam or crank bearing failures. This issue wasn’t resolved until 1994 with Morgan’s use of the Land Rover engine, when the heads were bolted to the block by 10 evenly distributed bolts.

In the original Plus 8, the Rover V8 was too torquey for the Rover manual gearboxes, so a Borg Warner automatic transmission was put in place. Thankfully, in 1971, Rover introduced an all-synchromesh four-speed manual ‘box for the 3500S saloon. As a result, Morgan customers were offered the same new gearbox in 1972. Chassis number R7475 was the first to receive the manual gearbox, but the last car to receive the automatic gearbox was chassis R7494, due to typical teething problems.

The new gearbox was based on the the Rover 2000 unit but with a stiffer casing, an integral oil pump driven through the back of the layshaft, taper-roller layshaft bearings and shot-peened gear teeth.

The four-speed manual gearbox was replaced with a similar unit but with five-speeds. This was produced by the newly merged BL/Rover group.

In terms of ownership today, parts for the original Moss automatic gearbox and four-speed Rover unit are unfortunately not easily come by.

SD1-engined cars came with a five-speed gearbox and parts are more readily available by comparison but are no longer produced; you’ll have to source from aftermarket companies, or from donor cars. Also note that from 1985, when the fuel-injected SD1 Vitesse engine was used, the internals between that and the previously used SD1 engine are not interchangeable.

That being said, it has been noted that most of the gearboxes used by Morgan are strong and reliable, and should the transmission oil have been changed regularly you shouldn’t have many issues. Morgan recommended using automatic transmission oil in all boxes, even in the manual variants.

You shouldn’t have many problems with later SD1 gearboxes, with many owners reporting that tuned Plus 8s running close to 300bhp and running regularly on track have held up well with correct maintenance. Officially the ‘box was rated at 245lb.ft but this figure is mostly always conservative.

Suspension, steering and brakes

The Plus 8 makes use of Morgan’s famous sliding pillar suspension system. Essentially, this was carried over from the 4/4, with the same Armstrong telescopic front and lever-arm rear shock absorbers being used. However, the top springs were one coil shorter at the front.

Again, as is the theme with Morgan, a good car is one that has been well maintained. Although that sounds obvious, many problems that arise are simply because maintenance was not kept up, and so it is with the suspension system.

Without getting too technical, an oil button was provided on the top of the transmission tunnel which allowed a trickle of oil to dribble down the suspension kingpins. By now, if not changed, that oil will have been contaminated and the phosphor-bronze bushes used will have been affected by this.

You should expect the bushes to wear every 15,000–25,000 miles due to the friction of moving up and down. When assessing a car to buy, you should check for breakage of the cross-tube lugs at the bottom of the suspension pillar mounts.

The suspension system is very firm, which has meant that some people have converted to telescopic rear dampers. This does improve the car but isn’t original, so depending on what you’re after, this may or may not affect your decision.

All Plus 8s have an extruded-mesh AC Delco-type collapsible steering column, which was fitted through a crowded engine bay. As the car – and more importantly the wheels – became wider, the car’s steering became heavier and heavier. It wasn’t until 1986 that that a rack-and-pinion system became standard. You can get an earlier car with the same system from 1984, but these are rare as it was an option costing £1100.

The cam-and-peg steering systems originally used will have now worn. Luckily for Plus 8 owners, the Burman system used is much the same as the Gemmer ‘box and they are interchangeable as a result. Also, an option for owners of early Plus 8 models is to switch entirely to the newer rack and pinion system. This removes some of the original characteristics but you’ll end up with a better all-round car.

No matter which steering rack is used, the track rod ends will wear and rust if not greased properly. Signs of worn or dried-up track rod ends include much heavier steering than usual – something to look out for on test drives.

Interior and trim

Check thoroughly for signs of water ingress – Morgan hoods are perhaps not the most watertight in the business, so it’s possible that at some point water’s got into the carpets. Anything here or trapped in the bulkhead is bad news for structural rigidity.

Trim scuffs are commonplace but expensive to sort properly, so we’d be looking for the nicest interior we could find. If any refurbishment is needed, it’s often easier to contact a good trimmer than it is to source replacement parts; a Morgan is a hand-made car and it’s better to trim what’s there than to try and make a generic item look right.

Morgan Plus 8: our verdict

A Morgan Plus 8 is about as British as roast beef on a Sunday. Not many cars come as British as the Morgan, a company that has existed for over a century despite all odds and is still producing cars to this day. It’s remarkable how accessible that heritage can be if you buy wisely – along with some serious bang for your buck thanks to that strong V8 powerplant.

As per most British sports cars there are a few key issues to look out for, but those looking to take the plunge needn’t too worried. With plenty of specialist and club support around, doing your research and asking the experts is the best way to avoid a basket case. Start with our guide and work from there.

The Morgan Plus 8 brings a serious amount of character for your money that’s hard to match in its market ballpark – we reckon it’s even worth taking an older Morgan for a spin if you’re in the market for a brand new one. Put the change towards a dream driving holiday and you’ll be very glad you did.