Range anxiety can still be a concern for EV buyers, so carmakers remain focused on making their electric cars go as far as possible. Here’s how they do it

Words: Chris Randall

Range is a precious commodity when it comes to electric vehicles. It has increased greatly since the first mainstream EVs arrived on the market when barely a hundred miles was often the most you could expect. Nowadays, plenty of models claim to cover more like three times that distance before a recharge is required, although such figures don’t often translate to real world driving.

The vagaries of the WLTP (World-Harmonised Light Vehicle Test Procedure) testing process means many EV drivers find range falls far short of what they hoped to achieve; if you assume that actual range will be around 75% of the claimed figure you won’t be too far out. But as car manufacturers employ ever-more sophisticated technology to help motorists eke out as many miles as possible, we’re taking a closer look here at how they do it.

Aerodynamics

Vehicle aerodynamics have been a focus for many decades, leading to major improvements in performance and fuel consumption, but it’s taken on renewed significance in the electric era. Says Nissan: “Aerodynamic testing is becoming increasingly important. The aerodynamics of electric vehicles are directly linked to how efficiently the vehicle moves – less drag and better stability allows the customer to drive longer distances before having to recharge.”

Posing a particular challenge when many EVs are bulky crossovers and SUVs, the traditional techniques of minimising panel gaps and employing flat under-body panelling have been joined by the even greater optimisation of individual parts such as wheels, door handles, and door mirrors. Using flush-fitting door handles that only pop out when the doors are unlocked, and replacing the traditional bulky door mirrors with small cameras are examples of the changes in design driven by the need to reduce drag, even if only by small amounts.

There’s also the careful balancing of cooling and aerodynamic requirements such as the Active Air Flap system on the Hyundai Ioniq 5. Hyundai say the difference in the coefficient of drag (Cd) is about 0.013 between open and closed, which is worth around 4.5 miles of range.

Brake energy recuperation

Often referred to as regenerative braking, it’s been employed on hybrid vehicles for many years, but it plays a much greater role on pure EVs where every bit of energy needs to be saved. Using the motor as a generator to produce electrical energy as well as slowing the car, maximising the energy that can be returned to the battery, requires increasingly sophisticated control to balance how much work is done by the motors and how much by the conventional brakes.

Porsche say its Taycan model can recuperate up to 290kW that’s fed back into the battery, while Audi say that braking from 62mph in an e-tron recovers 220kW, figures that can significantly boost range during the course of a journey. Adjustable levels of regeneration (via a pre-selected mode or steering wheel paddles) is another common feature, allowing many EVs to offer ‘one-pedal’ driving whereby lifting the throttle produces regeneration strong enough to bring the car to a halt without using the brakes at all.

And going a step further, Volkswagen equips its ID. models with an Eco Assistance system; analysing data from the navigation system and using the forward-facing cameras to detect road signs it can tell when the car is approaching a slower speed zone or a slower vehicle and reminds the driver to lift off the throttle, thus maximising energy recovery.

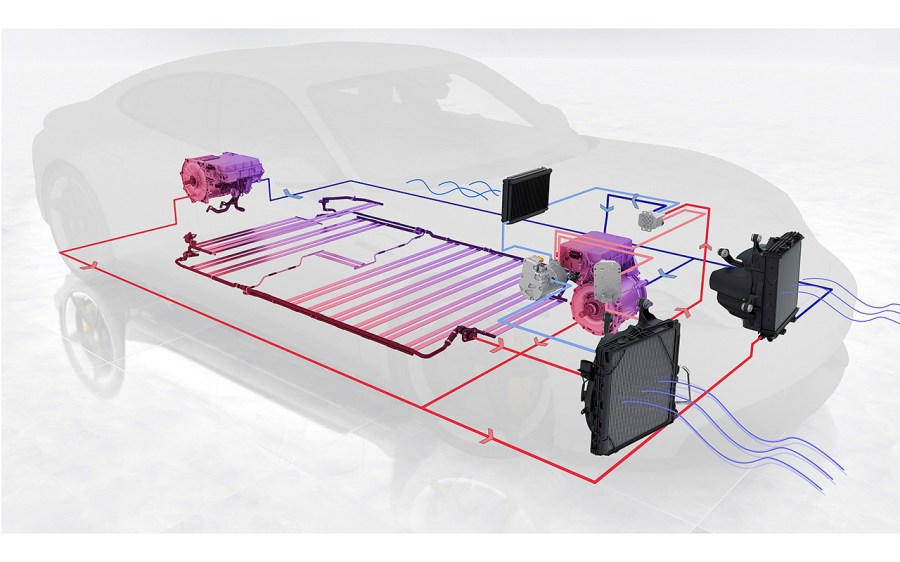

The heating and cooling circuits for the Porsche Taycan. Thermal management plays an important role in improving battery performance and range

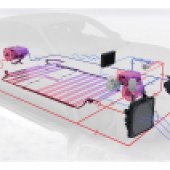

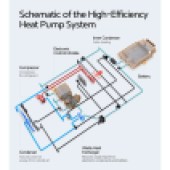

Thermal management

Batteries work at their best when operating in a specific temperature range, with around 30°C being considered the optimum (every EV driver will have noticed how cold weather can reduce range by a significant degree) which is why today’s models employ ever-more complex cooling and heating systems to manage battery temperature.

Extremes of hot or cold will have a negative effect on energy consumption, and thus range, so precise control is important. Constant measurement and adjustment within the cooling circuit(s) help maintain the battery at its best working temperature, taking into account things like driving conditions and climate control system use.

And more is done such as connection to the navigation system so that setting a route to a charger starts the cooling of the battery in preparation; Audi say that DC fast charging can heat the battery up to 50°C, so efficient cooling is crucial. And in colder temperatures waste heat from the powertrain and high-voltage components can be used to warm the battery, helping to minimise the reduction in range.

Energy saving

Using the energy within the drive battery to power systems such as climate control is going to reduce range. Which is why many EVs allow the driver to heat or cool the cabin in advance – often remotely via a mobile phone app – whilst the car is charging, reducing the need to use the system while driving. Driver-selectable modes are also employed which limit the amount of power diverted to the climate control system, or shut it down completely; for example, VW’s ID. models feature Normal (full climate control), ECO (less power to climate control) and ECO+ (all power to motors only) modes.

And a further piece of technology is heat pumps that utilise waste heat from the powertrain and high voltage components to warm the cabin, thereby reducing the energy required by the climate control system. EV maker Polestar claims it can reduce the latter by as much as 50% and in colder weather conditions range can be increased by 10%.

Volvo’s Range Assistant helps the driver to make best use of available battery power

Software updates

Today’s car companies spend a lot of time and money on software development, which can pay off when it comes to increasing EV range. It can result in all manner of incremental improvements, such as unlocking more usable power from a battery pack, improving thermal management and pre-conditioning, more effective regenerative braking settings, and altering how power is distributed between motors on dual-motor models.

This latter was the case for an update on an Audi e-tron model whereby the original set-up was changed so that now, in normal driving, only the rear motor was used, the front one being almost entirely disconnected and using no power from the battery. And Volvo is another example of a manufacturer used a software update to improve its EVs. In October 2021 improvements to its XC40 Recharge model not only included some of those outlined above but also added a Range Assistant app to the infotainment system.

Along with providing the driver with tips for more efficient driving it contained range optimisation functionality to adjust the climate control system and improve range. All of these things can be achieved via ‘Over-The-Air’ software downloads, so a useful boost in range comes with no inconvenience to the owner.