Modern Euro 6 diesel cars represent the most cost-effective motoring for many. Here’s all you need to know about AdBlue and the SCR system

Words: Rob Marshall

Once upon a time, diesels were promoted by governments that latched onto carbon dioxide (CO2) as the most harmful gas emitted by motorcar exhausts. Businesses and motorists alike lapped up the tax incentives and revelled in their fuel efficiency. As heavy-oil fuelled cars became more dominant, it was alleged that diesel exhaust fumes were causing notable air quality problems.

The majority of anti-pollutant measures on diesel engines are focussed on post-treatment technologies. These convert gases within the exhaust system, before they exit the tailpipe. Like a petrol engine, catalytic converters appeared on many models from the mid-1990s. These units facilitate chemical reactions but do not change themselves.

Diesels employ two-way catalytic converter, which convert poisonous carbon monoxide and hydrocarbons to carbon dioxide and water. Unlike the three-way catalytic converters, diesel cannot treat nitrous oxide (NOx) gases, due to the exhaust fumes’ higher oxygen content. As NOx gases pass through the exhaust system untreated, another way has to be found to address them.

A partial solution is to use an exhaust gas recirculation valve (EGR), which allows some exhaust gases to enter the engine’s cylinder again. While this seems to be a crazy idea, it reduces not only the temperatures at which NOx emissions form but also the quantity of fresh nitrogen and oxygen that enter the engine via the air filter. EGR, therefore, reduces the rate at which NOx forms at the source. To be even more effective, the exhaust gases have their temperatures reduced by the cooling system, before being drawn through the intake. These EGR coolers have become virtually universal.

With ever-tightening regulations, Euro 5 emissions focussed on tacking soot emissions. This resulted in diesel particulate filters (DPFs) becoming widespread to trap unburnt carbon particulates (soot) and, under certain conditions, burn them off into mainly harmless carbon dioxide and ash. The oxidising catalytic converter aids this process, by helping to increase the temperatures within the DPF.

Usually, maintaining the AdBlue fluid level and age is all you need to do. Familiarise yourself with the filler location. This one is in the boot.

Euro 6 emissions standards

The sixth stage of European anti-pollution legislation focussed mainly on waging a war on NOx emissions. Many (but not all) Euro 6 cars also tend to possess not one but two EGR circuits. The conventional high-pressure system works as before, extracting exhaust gases before they enter the DPF and cooling them within an EGR cooler (with or without bypass valves fitted), before entering the inlet manifold. A problem with this system is that sooty and oily exhaust gases congeal within the intake.

The second system involves low-pressure EGR, which takes clean exhaust gases after they pass through the DPF and recycles them through the intake to reduce NOx even more. Some cars possess electronically-actuated flaps within the exhaust system to prevent gases from being expelled, encouraging a faster flow of gasses into the low-pressure EGR. The engine management system is programmed to operate the EGR systems, when appropriate.

When looking at ways to meet Euro 6 legislative requirements, manufacturers selected two options. The least complex method was to rely on NOx storage catalysts and to utilise as much exhaust gas recirculation (EGR) as possible. While this arrangement is not covered within this feature, it is worth considering that the EGR circuits tend to suffer from wear and blockages.

The second system involves the heart of this feature: Selective Catalyst Reduction (SCR). Some manufacturers adopted this technology as early as 2004, although it became popular on engines larger than 1500cc after 2015. Yet, when considering SCR technology, one must consider that it cannot be treated in isolation; hence an appreciation of catalytic converters, DPFs and EGRs is useful.

This SCR catalytic converter on this Range Rover Evoque is pictured separated from the rest of the exhaust system. The long pipe is for the low-pressure EGR, which transfers clean, treated gases to the low-pressure EGR cooler within the engine bay.

How selective catalytic reduction (SCR) works

After the exhaust gases pass through the catalytic converter and the DPF, they enter the slective catalytic reduction (SCR) catalytic converter. The NOx content is converted subsequently into nitrogen gas and water vapour. Yet, the catalyst cannot facilitate this reaction on its own. To do so, it requires ammonia, which is stored and expended during the reaction. Ammonia is provided by a Diesel Emission Fluid, known by the brand, AdBlue. When injected into the hot exhaust system under certain conditions, the fluid’s passes through a mixer within the exhaust system, its water content evaporates, and ammonia becomes deposited within the SCR catalyst.

The engine’s ECU determines when and how much AdBlue to inject. The calculation utilises NOx and gas temperature sensors that are mounted to the exhaust. The former detects whether the SCR system is working properly; the latter ensures that urea deposits do not build within the SCR by ensuring that the AdBlue injector is not activated until the exhaust gases reach between 150-200°C, approximately.

The system is programmed to consider how the vehicle is driven and how much ammonia the system calculates is held within the SCR catalyst. Some models feature combined oxidising catalysts, DPFs and SCRs within the same canister, many of which have water-cooled AdBlue injectors. You may find an extra ammonia slip catalyst, too, which treats any remaining ammonia passing through the SCR catalyst, due to too low exhaust system temperatures, or a fault.

The AdBlue storage tank tends to be sited to the rear of the vehicle, within which lies a fluid temperature sensor. Should the temperature drop below a certain threshold (around -7°C), the internal defrosting heating element is activated, before the main pump operates, which transfers the AdBlue to the injector. You may find that the supply line is also heated, either along its length, or on the connectors. Certain cars also possess a separate control module to assess and control AdBlue heating, which communicates with the engine management ECU.

AdBlue tanks can be very sensitive to overfilling. Additionally, the level sensor may not be float designs but ultrasonic, programmed to require air space at the tank top. This is necessary not just for level sensor calibration but also to facilitate expansion, should the AdBlue freeze.

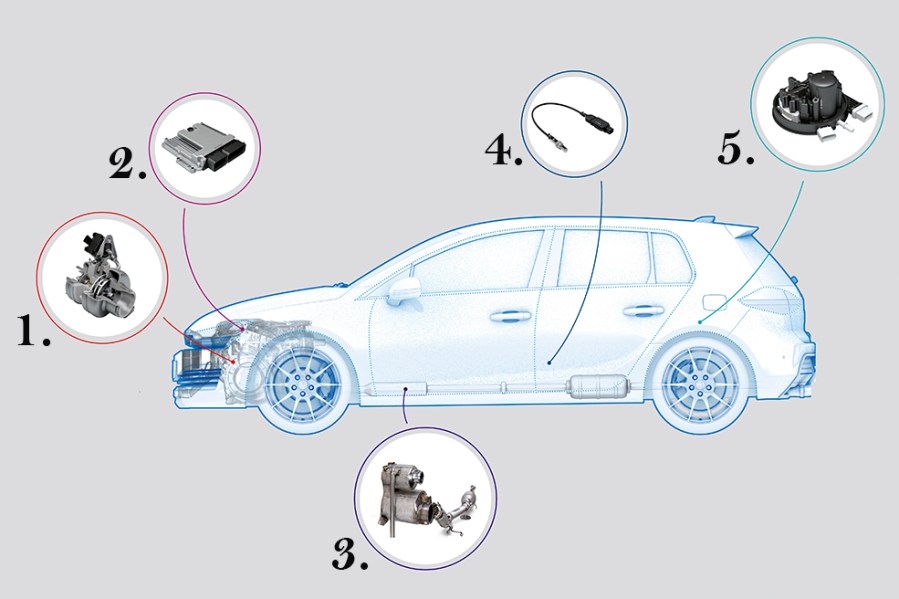

Selective catalytic reduction (SCR) main components

- The turbocharger plays a vital role in reducing emissions. Apart from reacting quickly to the driver’s input, it also is designed to optimise both the high and low-pressure EGR circuits. For sake of space, turbochargers are not covered within this feature.

- The engine’s electronic control unit (ECU) sends and receives data not just from the emission control system. Bosch says that a minimum of eight million lines of software coding are needed – a space shuttle requires half that.

- The manufacturer designs the exhaust system, the oxidising catalyst, the DPF and SCR catalyst to reach their optimum temperatures, quickly. To treat NOx, emissions must be kept above 200°C. Therefore, purchase quality replacement exhaust components that are Type Approved.

- The SCR system utilises mainly NOx and temperature sensors. These work alongside other sensors used by the DPF. They must work properly, so that the engine management system receives the correct information. This emphasises the importance of sensor quality, so be cautious, when buying replacements.

- The AdBlue delivery module includes the level and temperature sensors, pump electrical connections and DEF inlet and outlet connections. The unit is mounted to the AdBlue reservoir. The pump’s current draw tends to be the indicator of system pressure, which tends to be around 50-150psi. The pump returns DEF to the tank, when the engine is switched off.

- The AdBlue supply line is made from plastics and rubber that are AdBlue compatible, such as Viton and Polypropylene. You may find that the line possesses a heater element, so check that the electrical cabling and connectors are in good order.

- Mounted to the exhaust system, the AdBlue injector tends to be a relatively simple solenoid design. It possesses several spray holes, to ensure that the DEF is atomised as it approaches a mixing plate within the exhaust system, before entering the SCR catalyst. They can start leaking, causing their urea crystals to build on the tip. This can affect the spray pattern and over-saturate the SCR catalyst, causing clogging. When removed, check the injector for blocked spray nozzles, if an injector fault is suspected but its resistance is within tolerance.

What is AdBlue?

AdBlue (the brand name for Diesel Exhaust Fluid – DEF) comprises 67.5% pure water and 32.5% high-purity urea – it is not simply pig urine, as rumoured. When injected into the exhaust system, it forms ammonia, essential to convert NOx into nitrogen and water. It is harmless to your skin but it stains fabrics and corrodes certain materials, including steel and copper. Spillages should be mopped up with water. If allowed to dry, the solution leaves white urea crystals behind, which can be rinsed away with running water.

Unfortunately, AdBlue has a limited shelf life. The typical two-year lifecycle is reduced further if stored above 25°C, in an unsealed container, or if positioned in direct sunlight, because the urea decomposes. While you can use a dedicated refractor to test AdBlue quality, sniffing a sample will reveal if it is likely to be out of date. Usable AdBlue should not smell. Using degraded AdBlue is not recommended. The car’s NOx sensors can detect that the system is not treating the exhaust gases correctly and will deduce that the AdBlue quality is poor.

AdBlue is generally harmless but it is corrosive. You can rinse dried crystal deposits with water, provided the area in question is not damaged by moisture.

Should the system detect that NOx is not being treated effectively, or a low AdBlue level situation exists, it is a legal requirement that the engine cannot be restarted. This does not happen immediately; the driver is provided with plenty of notice. In many cases, this period can be more than 1000 miles. Should a lit Management Indicator Lamp (MIL) appear, address the issue as soon as possible, because this condition tends to prevent active DPF regenerations. This means that the DPF could become so full of soot that it cannot empty itself and, therefore, demand extra procedures (and expense) to clear it.

AdBlue consumption varies hugely between makes and models, plus driving, road and climate conditions. Jaguar Land Rover (JLR) sees 500 miles per litre as average consumption but this rate can double.