Lightweight, yet relatively strong, aluminium has become the product of choice for today’s motor manufacturers. However, if you thought this was a modern invention, you would be wrong. We take a look at how aluminium has shaped the history of the automobile.

The next time that you finish a soft drink or beer, and crush the can before sticking it into the recycling bin, spare a thought that it may yet end up as part of some manufacturer’s new model range. Aluminium is something of a wonder material. Not just thanks to its lightness and inherent strength but also because it is almost always recyclable. Indeed, some experts have predicted that if we can get our act together globally and recycle all the aluminium products that presently exist, there may soon be no need to keep mining the bauxite ore needed for aluminium. The one flaw in that environmentally friendly ideal is that demand is on the increase, significantly from the motor industry.

Today, there are many owners of new Jaguars and Range Rovers who probably don’t think twice that most of the structure of their car is made from aluminium. To an engineer it’s impressive, but to regular car owners it’s almost blasé. The intriguing fact, however, is that using aluminium in a motor car is almost as old as the car itself. In 1899 Nikolas Durkopp moved from producing sewing machines and bicycles into building motorcars and used aluminium for the bodies; the 1901 engine designed by Karl Benz had aluminium alloy bearings; in 1918 there was even a Norwegian motor manufacturer, Bjering, that produced an aluminium-bodied machine (complete with air-cooled V4, but that’s for another feature!). There’s even a story that when the first Alvis arrived in the 1920s, complete with its aluminium alloy pistons, that the company’s name was made up using the ‘Al’ from aluminium and ‘vis’ being the Latin for strength. Founding engineer Geoffrey de Freville always denied this, but it’s a good story and so deserves repeating.

Motorsport was one of the main reasons for the use of aluminium, as that was where the demand for light weight with strength was in greatest demand. One of the most famous race teams ever, the Mercedes-Benz ‘Silver Arrows’ of 1934 got their name from the bare aluminium bodywork, although the weight loss in this case was because team manager Alfred Neubauer needed to lose a kilo to meet the racing regulations weight limit and so decided to remove the heavy lead-based paint from his race cars!

The first significant road car application of aluminium was in 1936 when Carrozzeria Touring patented its ‘superleggera’ coachwork construction technology; small diameter steel tubes are formed to construct the vehicle’s bodyshape, to be covered by thin, lightweight, alloy body panels. This led to numerous sporting designs and is a word still used as a model name for some of the most expensive cars produced. That same year saw the launch of the BMW 328 roadster, not only did it have a full aluminium body, it also had an aluminium cylinder head. Some interesting skulduggery after the Second World War saw some of BMW’s technical details (together with BMW’s engine design chief Fritz Feider), finding their way to England and the Bristol Aeroplane Company, later to become the Bristol Car Company. A great deal of knowledge on using aluminium came across to the UK.

It was only a few years after the Second World War when aluminium was used in one of the most famous vehicles ever built, the Land Rover. Ironically, the use of aluminium panels on the original Land Rovers was not done for any specific technical benefit, simply that it was readily available when steel was expensive and in short supply due to the war. Of course, the most ironic part of the story is that while the aluminium panels did not rust, the rest of the world’s most significant four-wheel drive certainly did, notably the steel box section ladder chassis. Fast forward to today, and aluminium has taken over as the material of choice for entire monocoques bearing the ever-growing Jaguar Land Rover model range.

The need for strong, malleable and light materials has always been a key to motorsport success and so it’s no surprise that aluminium was the body of choice for many race teams, none more so than Jaguar. The competition C and D-types in the 1950s did much to establish the company’s sporting reputation (five Le Mans 24 Hour victories in this period helped here). Success on the track created great demand for road-going sports cars and such was the demand that the very first 240 versions of the XK120 were actually built with aluminium bodies over a wooden skeleton, before they moved to steel mass production.

The end of the 1950s saw the introduction of some of the most famous road cars to make full use of aluminium. The Aston Martin DB4 of 1958 had a platform steel chassis but then used the superleggera system for its curvaceous aluminium bodywork, styled by Carrozzeria Touring of Turin. The Italian company had been involved in a number of Aston Martin aluminium-bodied specials, but the DB4 was a significant step forward, which would be carried over to the DB5 and DB6.

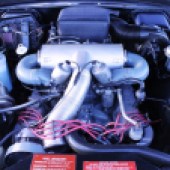

The beginning of the 1960s saw the use of aluminium for one power unit that was to become one of the most versatile and successful ever built. America had been leading the way in using the material in engines and the launch of the Buick 215 all-aluminium V8 in 1961 was a significant date. It was a particularly light V8, but capable of high power outputs. The engine was used at the 1962 Indy 500 race by the Mickey Thompson race team, driven by the then-novice Dan Gurney, and while it didn’t finish (no fault of the engine), it was very competitive and was actually entered by the sponsor, Harcraft Aluminium. Cross the Atlantic and Rover was on the look-out for an American V8 for British cars. The Buick unit fitted the bill perfectly, it was actually lighter than some of the four-cylinder engines it was due to replace. The deal was done in 1965 and the Rover V8 was introduced to the UK market. Not only did the engine find its way into a significant number of Rover models, but the company took the unusual, but ultimately highly profitable decision to sell the engine to other small car builders, meaning the engine was used by the likes of Morgan and TVR, as well as in Rover’s own Land Rover and Range Rover. Now, we could fill a book describing the vehicles that benefitted from this V8, but one of the most significant has to be the Rover P6, a car that won many industry awards as the 2000 before even greater success when the V8 was squeezed under the car’s (aluminium) bonnet.

Using aluminium for non-stressed body panels like the bonnet became a useful method of increasing a car’s performance. Colin Chapman replaced the bonnet, door skins and boot lid on the Ford Cortina, which together with alloy differential casing and gearbox bell-housing not only helped reduce the weight to create the Lotus Cortina, it also gave the family saloon turned boy-racer macho machine additional kudos. Aluminium additions and tweaks became mainstream, and they became sexy.

Aluminium engines did not always sweep all before them, but we can look back now and see that some manufacturers were very brave in their decisions. If you were going to build a competitor to the ground-breaking Mini, for example, it’s hard to see that you would actually come up with the Hillman Imp, but Rootes did! Building a boxy, rear-engined car is quite a dramatic step, fitting it with a new unproven all-aluminium engine certainly shows confidence. The new 875cc engine remains something of a gem, but does need looking after. Overheating from head gasket failure marred its reputation somewhat, but it understandably has some enthusiastic followers today.

In America, Chevrolet decided to go along the mass produced aluminium engine route with its 1971 Vega model. This used an aluminium four cylinder block, but it was unlined and liable to scoring, excessive oil burning and premature – and terminal – engine failure. Add to this the fact that the Vega’s steel body managed to rust nearly as quickly as the engine expired and it can be classified as one of Chevrolet’s more embarrassing models. The man in charge at the time was a certain John DeLorean; whatever happened to him, we wonder?

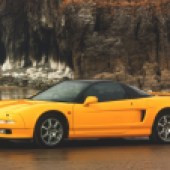

In the mid-1980s, a group of engineers started work on a project that was to become one of the most significant, if often overlooked, production motor vehicle in the whole aluminium story. Those engineers worked for Honda, a company that had built an enviable reputation for reliable, if somewhat conservative, mainly front-wheel drive family cars. However, in 1983 Honda had returned to Formula 1 Grand Prix racing as an engine supplier. By 1988 they were providing engines to McLaren, which employed Ayrton Senna as their number one driver. Honda now had serious racing credentials and felt the time was right to launch a sports car. They needed something with charisma and it had to be special since the company had no obvious brand heritage to base it on; aiming at the likes of Ferrari and Porsche with a sports car was quite a challenge.

The Honda engineers approached the project in a very analytical way, comparing the performances of existing sports cars (weight, power output, wheelbase, stopping performance) and mapped them on a graph. Included on this was McLaren’s (very successful) F1 race car with the intention of getting the specification of the new sports car closer to the F1 spec and away from the competitors. Weight became the most important parameter and the initial designs looked at a mix of aluminium and steel, but that didn’t fit the graph and so it was decided to build the entire monocoque and body in aluminium; now that’s a very simple sentence to write, but they were proposing to do something that had never been done before and it was to be a high performance supercar. Although only around 20,000 were ever built, the Honda NSX deserves the accolade of being the first mass production car to offer an all-aluminium monocoque body. Senna actually drove a prototype and was impressed, but questioned whether it was strong enough. The engineers went away and improved the stiffness of the monocoque. Launched in 1991, the Honda NSX remains an exceptional mass production supercar.

While the NSX was a supercar, and so limited in its market, Audi went for the numbers when it produced the A2; a complete aluminium monocoque supermini. It also had a very low drag coefficient, highly efficient engine options and a number of automotive firsts including low rolling resistance tyres. It was also ugly, lacking in character and more importantly very expensive to produce and so that cost had to be passed on the buyer. Only 176,000 or so were built, many more than the NSX, but considerably fewer than the Mercedes A Class it was up against. Despite this failure (Audi is said to have lost money on every A2 sold), the German company continued with its aluminium plans and in 1994 produced the aluminium-chassised A8 saloon, a model that has been far more successful and developed a wide and varied model range.

In 1996, another car arrived with an aluminium chassis, this time an aluminium extruded, race car-like ‘tub’ design, glued together, onto which the suspension geometry was bolted, with the whole lot covered with a glassfibre body – enter the Lotus Elise, the biggest selling Lotus ever produced and one that has kept the company both financially alive and relevant in today’s sports car market.

Despite having used aluminium in bodies and engine mechanicals since the 1940s, it wasn’t until 1999 that Ferrari responded to Honda’s NSX with the 360 Modena aluminium monocoque design. As 2000 arrived, you can see aluminium being used in a variety of models. Morgan came with the strikingly original, some might say bizarre, Aero 8. Jaguar made a statement of the way that company was thinking with the X350 saloon complete with its all-aluminium monocoque body that was claimed to be 40 per cent lighter and 50 per cent stiffer than the previous steel XJ model range. The production techniques used on this car have now been developed further for the latest Land Rover and Range Rover model range which, despite the fact the majority only go off-road to park at county fairs are still supreme when driven in the rough, proving that aluminium has the strength and body stiffness to cope and point the way to the future of mass production vehicles. It also has the advantage that when such a car expires, it can be recycled to build a new one.

Today, models as varied as Rolls-Royce and the latest Ford F-150 pick-up benefit from the use of aluminium monocoques. Tesla uses aluminium panels to protect the battery compartments from any shock or accident damage and are looking at using aluminium-titanium plates for high speed protection vehicles, since aluminium absorbs shock much better than steel. The new ideas and uses of aluminium for the motor car show no signs of decreasing. So, remember that when you finish that can of coke or fancy craft beer, make sure you recycle it, as you never know where it will turn up next.