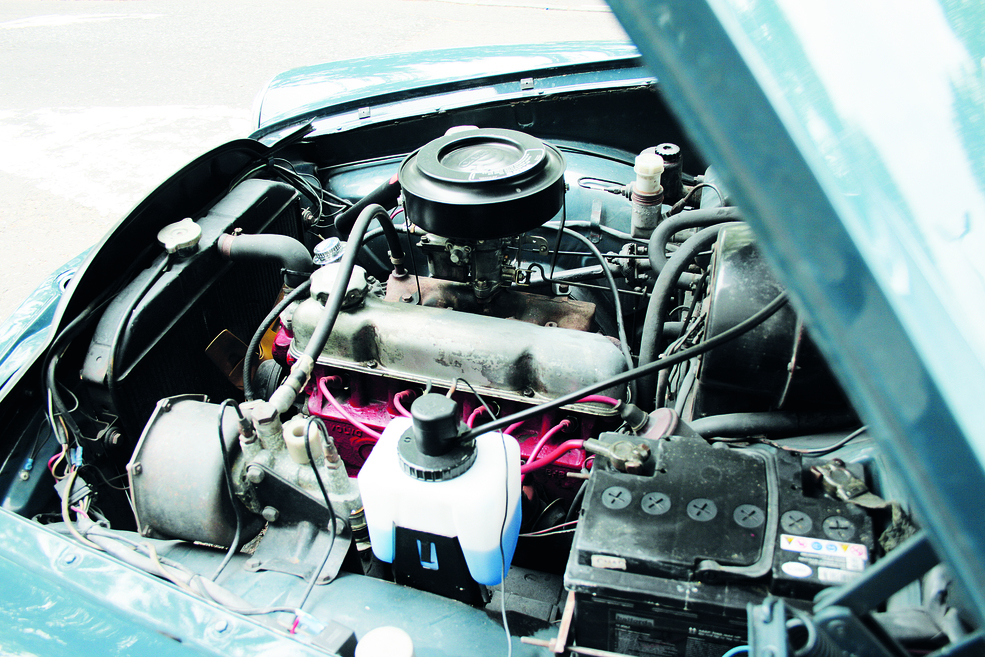

Volvo’s B-Series engine will be familiar to most readers as the powerplant used in the Amazon and P1800 lines but its origins go back way further to the Volvo PV444 introduced in 1944. The firm’s first inline four-cylinder engine since the 1920s, it was known as the B4B and displaced just 1414cc through its single downdraught carburettor.

Using a cast iron block and head with valves operated by pushrods, it was a robust if unadventurous design and later became the B14A with the addition of twin SU carbs.

In 1957, the unit was bored out to 1583cc to become the B16 (single carb) and B16A (twin carbs), offered in the PV444 until 1958 and then in its successor the PV544.

Although Volvo also used versions of the B-Series engine in other areas of its business including marine and agricultural powerplants, its first volume application was the Amazon range launched in 1956.

The B16 was visually similar to the earlier engine although the oil filter was sited under the manifolds and the manifolds themselves were reshaped.

Bigger change came in 1962 when the B16 became the 1778cc B18, again offered in single-carb B18A and twin-carb B18B formats but now with five main bearings. The engine now boasted a 12-volt electrical system and would prove to be a mainstay Volvo powerplant for the life of the Amazon.

Four versions of the B18 were produced from A to D, the letters denoting camshaft grinds. The A variant was reserved for the basic 121 model, with a single carburettor (initially Zenith, later Stromberg), low compression pistons and a mild cam. The B18B was introduced in the now sought after 123GT model in August 1966. Offering the highest power output (115 bhp) and specification, these were the range-topping Amazons, featuring a three-spoke steering wheel, auxiliary driving lights and Recaro-designed reclining bucket seats.

Discounting the B18C that was primarily used in military applications, the B18D powered the 122S, a mid-level specification with twin SU HS6 carburettors and 90 bhp against the 121’s 75.

Power outputs rose slightly for the B18A, B and D engines until 1967 – at that point the new B20 unit intended for the new 140-series became ready. The B20 was created by boring out a B18 from 84mm to 88.9mm, and was fitted to all Amazons after 1968. The engine features split bore centres, meaning a greater spacing between the centre cylinders than the outer pairs.

Again, the B20 was available in several different versions. The 8.7:1 compression, single-carb B20A was good for 82 bhp and the B20B was a twin-carb version running 9.5:1 compression and 118 bhp.

Bosch D-Jetronic was used for the injected B20E producing 135 bhp from 10.5:1 compression and the emissions-friendly B20F with 8.7:1 compression and good for 118 bhp. Both the injection engines featured enlarged porting and bigger valves.

The B18 and B20 also appeared in the Volvo 140 series, with the D-Jetronic injection replaced by the simper analogue K-Jetronic system for the final year of production in 1974.

The engine was destined to disappear from passenger car production with the launch of the 140’s successor the 240 but the B20 did make an appearance in very early production 240s before being replaced by the overhead-cam B19 design.

Meanwhile, the engine lasted until 1981 in the Volvo military truck known as C202 in its military form but more commonly by its Laplander nickname. Really not a bad innings for a design which had first fired in 1944.

Strengths and weaknesses

Oil changes are needed every 3000 miles, with spark plugs and air filters being replaced at 12,500 mile intervals. British specification engines were specified to run on 10W/30 or 10W/40 mineral oil in period, but many owners prefer classic 20W/50 as engines age and tolerances widen. It’s always worth buying genuine Volvo oil filters, too – they’re fitted with a relief valve which maintains oil pressure from the moment you turn the key.

The breather gauzes are also worth cleaning at each service – there’s two of them. One is located in the filler cap, the other in a cam-shaped housing on the right-hand side of the engine block. These can easily clog up and contribute to heavy engine breathing.

The basic 121 models used a single Zenith 36VN or Stromberg CD175 carburettor. 122S and 123GT variants breathed through a pair of SU HS6s. Rebuild kits and new linkage parts are available for all, although in the case of the former it’s worth retaining the original jets and float valves as parts within Zenith overhaul packs can vary. 36VN-carburetted cars also use an all-in-one air cleaner with the element sealed in – the entire unit should be thrown away at each service. Other models have replaceable filters.

Balancing the twin SUs can prove difficult, but the clubs will have technically minded members in your area who can help.

Using an Amazon every day throws up a few common problems which various specialists have tackled. One such issue is the rear crank oil seal. The factory specified felt from new, which deteriorates in time leading to oil contamination of the clutch. The solution is to fit a neoprene seal into the housing. It’s a specialist job, with Amazon Cars and Brookhouse offering reconditioned seals on an exchange basis – send your old part in and a surcharge is refunded on its replacement.

Weaknesses in the timing gear can also show up on older engines – the original fibre teeth can break up in use. These can be supplanted with alloy items although they are noisier in use.