The close of 2023 marked 20 years of the all-aluminium X350 XJ – a car that was quietly but massively significant for Jaguar

Currently sitting on my driveway courtesy of our company’s ever-changing fleet of project cars is a Bentley Continental Flying Spur, which weighs in at a hefty 2.5 tonnes, that mass being the main reason why it needs a 6-litre engine, 12 cylinders and two turbochargers to provide performance worthy of the price tag.

And that’s generally been the inescapable law of physics relating to luxury cars, ever since the dawn of motoring: a big heavy car needs a big heavy engine which needs big quantities of fuel to propel it at acceptable pace.

The fact that luxury cars didn’t actually have to be quite so heavy was conveniently overlooked in Munich, Stuttgart and Crewe but Ford Motor Company was keen to investigate the weight-saving properties of using aluminium in car construction and it was one of the few occasions where Jaguar’s low sales volumes – tiny by Ford’s global standards – was a benefit.

The low production volumes and high retail prices of Jaguar products presented an ideal opportunity to trial the new technology with a generally lower risk level and a greater ability to accommodate the extra cost.

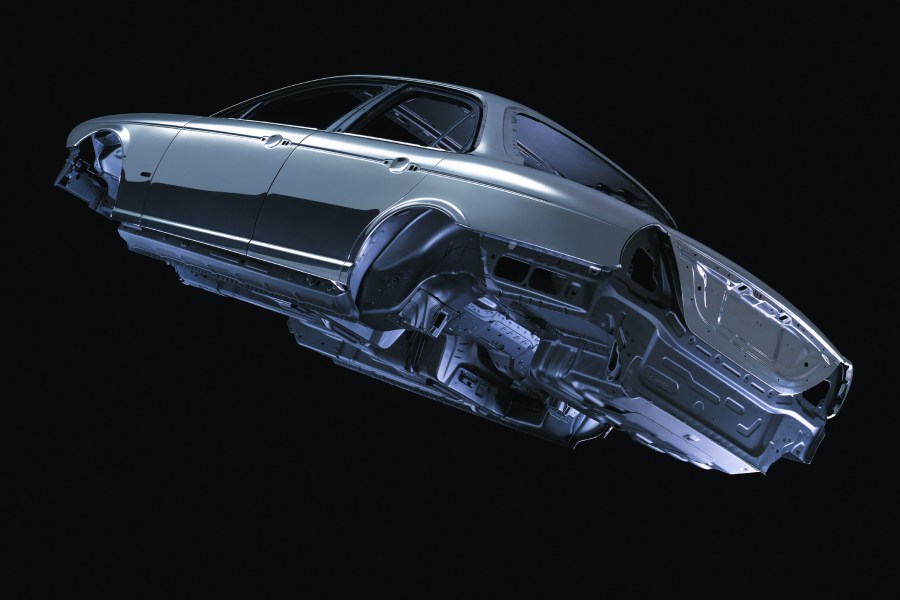

The idea of making entire cars (rather than outer panels) in aluminium wasn’t new, since Audi had debuted its aluminium A8 back in 1994 but the way Ford and Jaguar wanted to do it would be a new departure. Whereas Audi’s approach was to use a cast aluminium spaceframe carrying unstressed outer panels, the Jaguar would be a true aluminium monocoque bodyshell.

The idea had originally been borrowed from the aerospace industry, which routinely uses a system of self-piercing rivets and epoxy bonding to join aluminium sections and create structures with light weight and great strength. Since this hadn’t been used in the automotive industry before, much development work was required in order to adapt the technique and Jaguar combined the use of aluminium castings and extrusions with the riveted and bonded jointing technique to good effect.

The first car to benefit from the new technology would be the replacement for the X308 generation of XJ, which was given the code name X350 and developed with an eye to the crucial American market. Focus groups had identified a need for increased interior space – traditionally a handicap of the older XJs – and a larger boot, capable of taking four sets of golf clubs.

Making the car larger without saving weight would have put the XJ at a big disadvantage in the marketplace against its competition, which made it an ideal candidate for the aluminium technology.

The style of the new XJ was similarly arrived at after extensive customer clinics and it was these which dictated a more conservative style rather than highlighting the high technology under the skin by using an avant garde design. Given these requirements, the immediately obvious ‘Jaguarness’ is a credible achievement given the very different proportions of the X350: the wheels are pushed out to the corners, the bonnet is shorter and the windscreen shallower than previous XJs.

The appearance of the car was also influenced from several different directions and there’s a delightful urban rumour detailing styling chief Geoff Lawson’s response to a demand from the sales and marketing people for a specific boot capacity. Restricted by the exhaust system underneath and unable to borrow any space from the rear cabin or extend the rear overhang, Lawson calculated that to achieve the required boot space would mean the boot lid would end up half-way up the rear screen. To emphasize the point, he had a clay model made and presented to the sales people who duly accepted defeat.

Engineering issues also impacted on the car’s style, specifically those relating to the choice of aluminium as a material. Back in the late ’90s, aluminium technology in the automotive world was in its infancy and it was discovered that the material couldn’t be formed to quite such crisp lines or tight radii as was possible with steel. This had a direct impact on the shape of the final production car – notably the upright rear C-pillar and the convex shape of the lower door skins which is intended to prevent ‘oil can’ distortion issues. The car had originally been styled with a ‘six-light’ greenhouse but this proved impossible to stamp accurately in aluminium, which explains the move to a four-light style.

The wide panel edge flanges required by the aluminium construction also forced the use of LED rear lights which could be made in a shallower package to fit around the flanges. Despite these constraints, the final production car boasted a Cd of 0.32, which was good going.

An additional challenge was posed by the aluminium Jaguar being unique in the marketplace, which meant consideration would need to be given to any specialist crash repair techniques required. The shell was designed to withstand an impact of 10mph without structural damage and the frontal section was a bolt-on module incorporating aluminium ‘crash cans’ designed to absorb impact energy.

The bodyshell was to be assembled in the Castle Bromwich plant which would eventually become the marque’s centre for its aluminium-bodied models, with final assembly taking place at Browns Lane until 2005. The production line included six Schuler presses to produce the major pressings like outer panels and floor sections, with seven presses on a second line creating the smaller structural stampings.

It was noticeably different from the steel-bodied cars since instead of welding, the 88 robots were punching in self-piercing rivets and applying the epoxy.

Each example of the X350 used 15 aluminium castings for suspension and driveline mounting points, 35 extrusions found in the doors, bumpers, floor and roof structure and 284 stampings, with over 3000 rivets and 120m of adhesive. Magnesium also featured in the dashboard crossmember and seat frames.

The epoxy would only be fully cured when the car passed through the 170°C temperature of the paint oven. The Grade 6111 aluminium used for the outer body panels – also known as ‘bake hardenable’ – stiffens in the heat of the paint shop to better resist car park dents and similar.

The bonnet and boot panels meanwhile were assembled with the same adhesive but without the rivets, the inner structure and outer skin of each being attached by a technique called spot-clinching which physically folds (‘clinches’) one piece over the other under high pressure.

The state-of-the-art production process allowed a precision not often achieved in previous models: the X350 boasted door panel gaps of 3.8mm and bonnet/boot panel gaps of 3.5mm

Despite the challenges of engineering a full aluminium monocoque, the finished product turned out to be immensely strong – at 21,700 kg-m/deg torsional rigidity it was 60 per cent greater than the older car while being 40 per cent lighter.

The underpinnings were a similarly radical departure for Jaguar, using subframe-mounted double wishbone layouts at front and rear, dispensing with the traditional Jaguar IRS found under the outgoing model which could trace its origins back to the E-Type.

The car also adopted air springs all round, which provided a self-levelling capability as well the ability to add Jaguar’s CATS adaptive damping and automatically lowering the car by 15mm at 100mph.

The X350 would be launched at the Paris show in September 2002 and the first deliveries would commence in Spring 2003. A long-wheelbase model would be added in 2005 with a five-inch stretch to the rear doors and in 2007 the car would receive a minor facelift to become the X358 with the signature grilles in the front wings.

In 2009, production would cease after 83,518 cars but the technology which had been introduced with the X350 would remain a Jaguar hallmark: the second-generation XF, the XE and the final generation of XJ would all use aluminium monocoque construction, as would the XK and F-Type.

Aluminium pioneers

Despite the weight-saving advantages of aluminium, it’s not been widely employed in vehicle assembly. Many cars claim a high proportion of aluminium in their construction, but only three other volume car makers have created designs using an exclusively aluminium structure.

Audi’s A8 has always employed the Audi SpaceFrame (ASF) system, as did the shortlived A2, while Honda has also used a similar method for the NSX supercar and the Insight hybrid. Lotus, meanwhile, used an extruded aluminium chassis for the ground-breaking Elise and its derivatives, but no other mainstream production cars have used a fully aluminium construction.