By Jamie King

Estimated reading time: 20 minutes

The Ford Mondeo ST24 occupies a fascinating corner of fast Ford history. It was the first model ever to wear the ST badge, long before Fiesta STs and Focus STs became household names, yet for years it has remained overlooked and undervalued.

Here at Classics World, we’re passionate about affordable, usable classics – cars that normal enthusiasts can buy, work on, and enjoy without needing concours budgets. That’s exactly why we took on this £500 Mondeo ST24 project, documenting every stage of the restoration for the magazine and here on the website.

This article brings together Parts 1–6 of the project so far. Future updates will be added as the build continues.

Table of contents

Project ST24 Updates

- Part 1: Buying a £500 Mondeo ST24 – what we bought and why

- Part 2: Welding repairs – arches, sills and floor

- Part 3: Interior repairs, ST200 leather upgrade & headlining retrim

- Part 4: Rear suspension and brakes overhaul

- Part 5: Front brakes, calipers and suspension inspection

- Part 6: Engine service and V6 health check

- Part 7: Coming soon

Why the Mondeo ST24 Matters

Launched in the late 1990s, the Mondeo ST24 was never about headline-grabbing performance. Instead, it offered refinement, torque and effortless pace thanks to its 2.5-litre 24-valve Duratec V6. With around 170bhp, it was more motorway missile than hot hatch — but that smooth V6 soundtrack and understated styling gave it a character all of its own.

Today, values are beginning to rise, and with fewer than 150 examples left on UK roads, the ST24 is firmly entering modern classic territory. Compared with Escort and Sierra fast Fords, it still represents excellent value — for now.

The £500 Starting Point

Our project car is a 2000-registered Panther Black Mondeo ST24 showing 122,000 miles. It wasn’t pretty when we bought it. The paint was tired, the arches were bubbling, the interior was worn and the underside looked scruffy.

But crucially, the fundamentals were sound. The structure, sills and floor were far better than expected for a Mk2 Mondeo, making it a viable restoration rather than a lost cause. With help from Mark at Ford Parts R Us, who has supported the project with parts and advice throughout, we got stuck in.

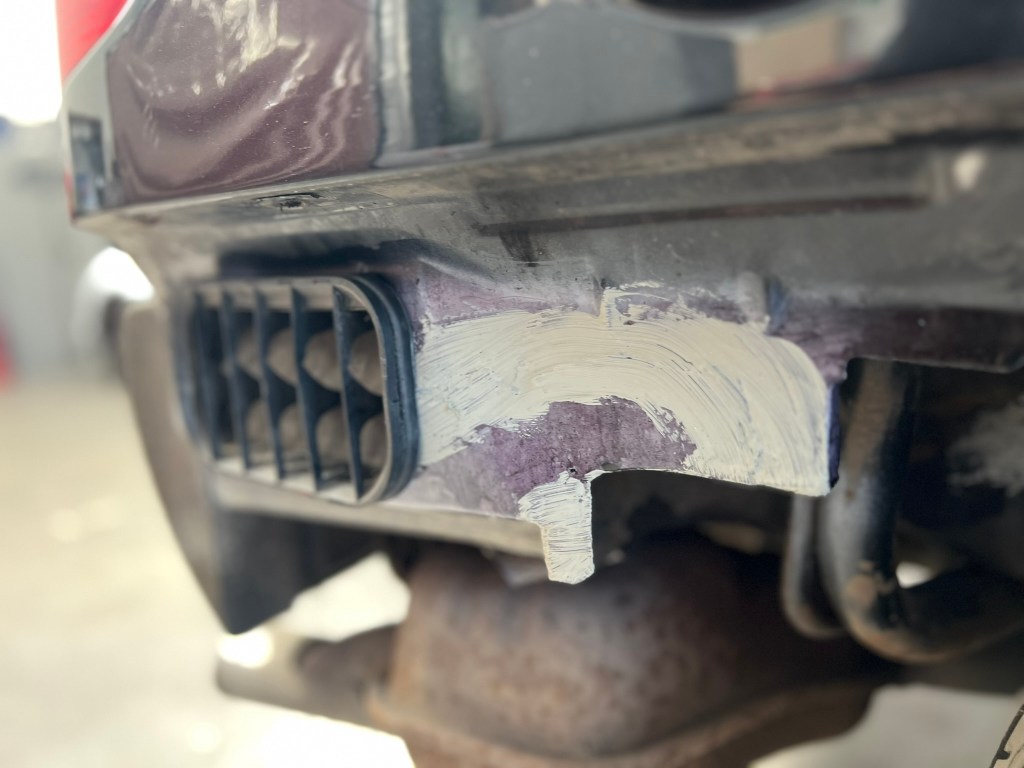

Welding and Rust Repairs

As expected, rust had taken hold in the usual Mondeo areas: rear arches, inner arches, sills and a small patch beneath the rear seat. The interior was removed to inspect everything properly, and thankfully none of the corrosion was structural.

Fresh steel was let in where required, including repair sections cut from replacement rear arches. Once welded, all repaired areas were sealed, painted and protected, saving the car from the fate that has claimed so many ST24s.

Interior Repairs and an Unexpected Upgrade

With the interior already stripped, we tackled the cabin next. The original half-leather ST24 seats had split stitching, and the driver’s seat height adjuster had failed – both common Mondeo issues.

We repaired the height adjuster using a £25 online repair kit featuring a brass replacement gear. It wasn’t an OEM-perfect job and needed fettling, but perseverance paid off and it worked smoothly again.

We also attempted to restitch the seats using a curved needle and heavy-duty thread. While the repairs were strong, they weren’t pretty – and evidence of previous bodged repairs confirmed these seats had already lived a hard life.

Ironically, the day after refitting them, we found a complete leather interior from a Mondeo ST200 for just £100. Aside from the usual broken height adjuster (now easily fixed), it was in fantastic condition. The swap transformed the interior instantly.

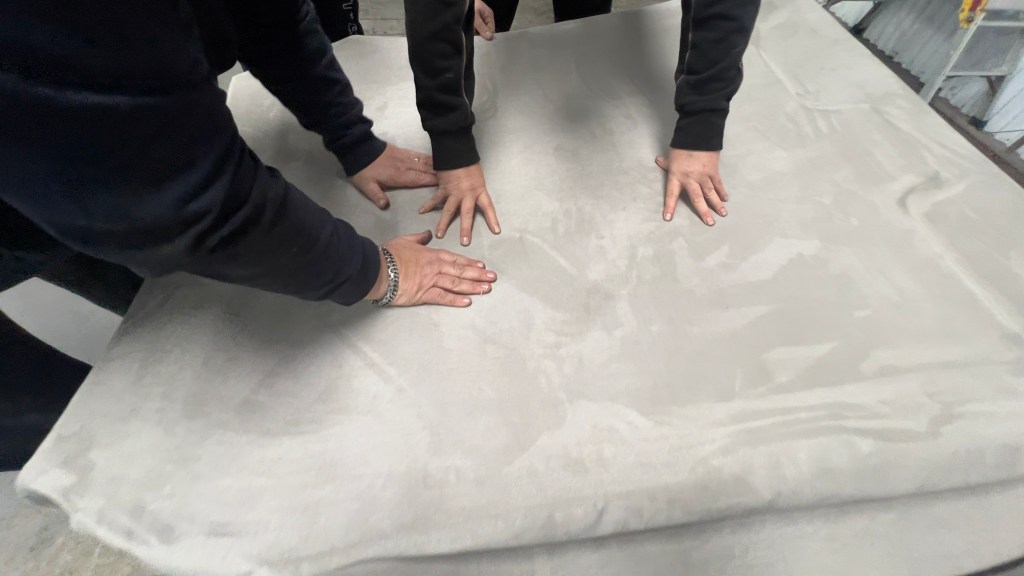

To finish things off, the sagging headlining was retrimmed in new cloth. This was actually quite a satisfying job; simply pop off the grab handles and interiro lights, remove the headliner from teh car, and then peel off the old farbic. Clean up the old loose bits of foam, and then you’re ready to apply the new fabric with nothing more than some spray adhesive. And it makes an instant transformation too. Loose trim was refitted, rattles eliminated and the entire cabin deep-cleaned.

Rear Suspension and Brakes

Underneath, the rear suspension revealed cheap aftermarket lowering springs that spoiled the ride and stance. These were removed and replaced with genuine ST24 rear springs, restoring factory ride height and comfort.

Every component was stripped, cleaned with wire brushes and inspected. Despite heavy surface rust, everything was solid. Rusted bolts fought hard, but Liqui Moly Rust Solvent made all the difference.

Rear discs and pads were replaced with new Febi Bilstein items , while bushes, brake lines and cables were checked and found to be in good condition. Stonechip was applied to repaired areas and the underside, followed by underseal and Lanoguard for long-term protection.

Front Brakes and Suspension

At the front, one caliper was seized – noticeable even when pushing the car around the workshop. Replacement calipers are still available for around £50 per side, but we opted to refurbish the originals using a £25 rebuild kit with new pistons and seals. We weren’t going to spend 20% of what the car cost us on a pair of calipers!

The original calipers were stripped, cleaned and rebuilt – not painted, just returned to clean, serviceable condition. New Febi Bilstein discs and pads were fitted, and the braking system was bled the traditional way: one person pumping the pedal, one on the nipple.

Mk2 Mondeos – especially V6 models – are known for tearing up front wishbone bushes. We had replacements ready, but ours were in excellent condition, saving us a job… for now.

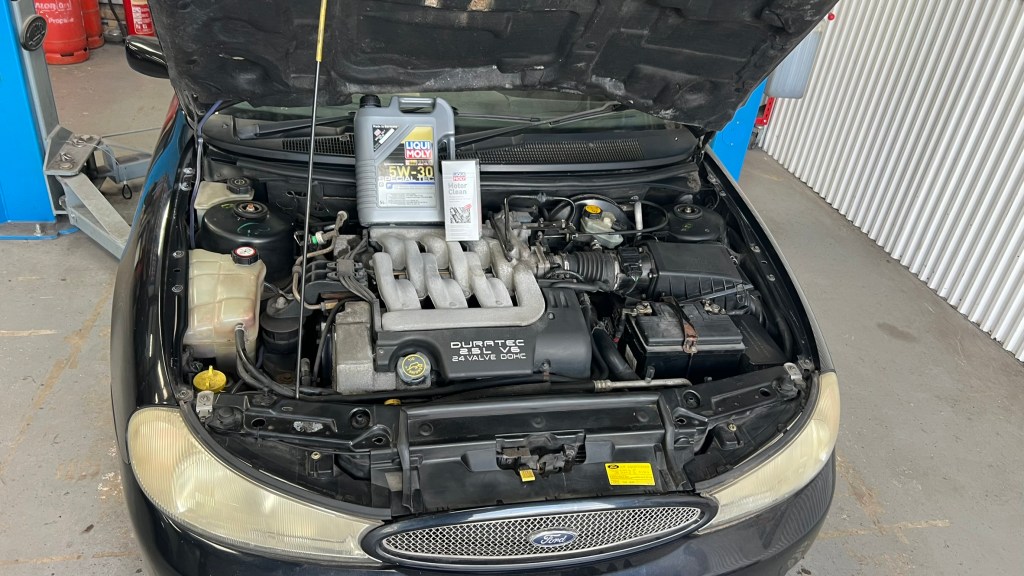

Engine Service: Looking After the V6

With the chassis sorted, attention turned to the Duratec V6. Before draining the oil, we added Liqui Moly Motor Clean, an additive that breaks down internal deposits. Once added, the car must not be driven, as it significantly thins the oil. Instead, the engine is idled for ten minutes to circulate the cleaner.

The old oil was then drained — black and filthy, showing the additive had done its job. A new Febi Bilstein oil filter was fitted, followed by Liqui Moly Special Tec 5W-30 oil.

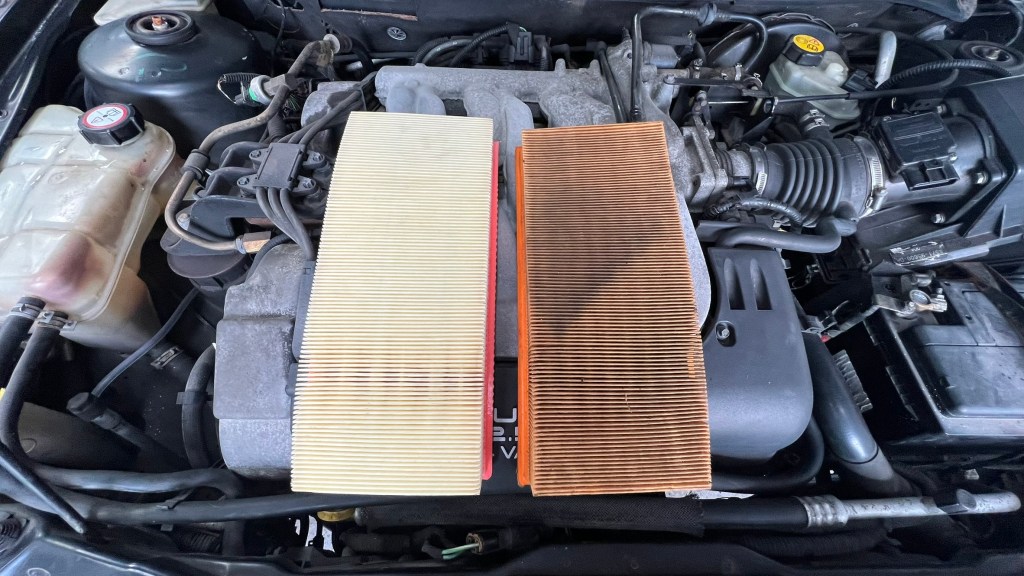

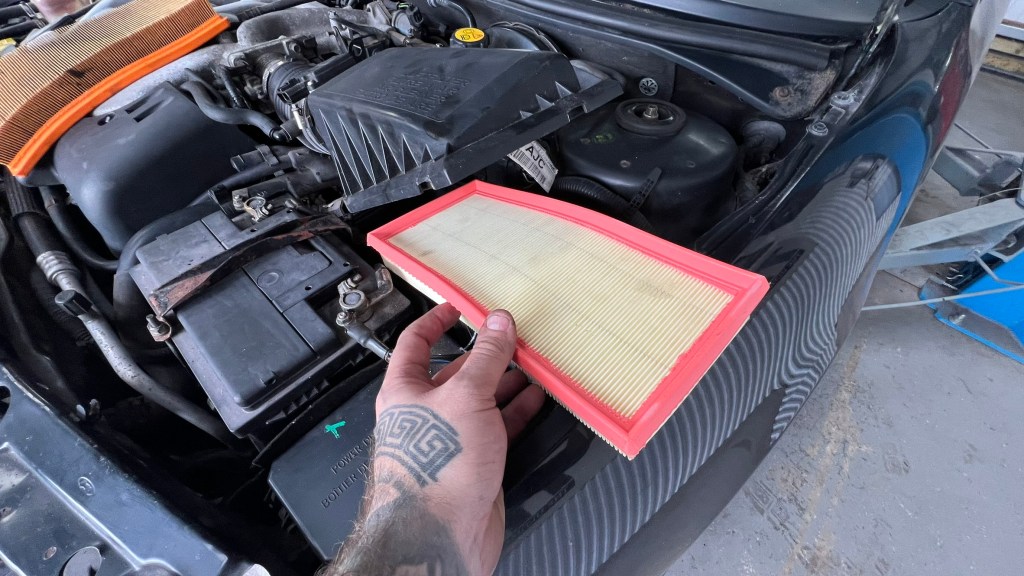

We also replaced the fuel filter, air filter and pollen filter. HT leads, auxiliary belt and hoses were inspected and found to be in good condition. Finally, the engine bay was cleaned and detailed, restoring a factory-fresh appearance.

Where the Mondeo ST24 Project Stands Now

At this stage, our £500 Mondeo ST24 is:

- Structurally solid

- Fully braked front and rear

- Properly suspended

- Fully serviced

- Clean, comfortable and presentable

The car hasn’t yet been driven on the road, but everything is now in place for that next step. Future updates will be added to this page as the project continues.